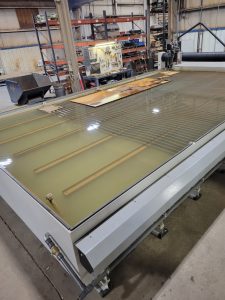

Our NEW OMAX Water Jet is capable of processing up to 8″ thick material with a width up to 160″ and a length of 310″. The system is also able to handle a wide array of materials including steel, aluminum, composites, rubber, ceramic, and stone. The mechanism creates a ready-to-use satin, smooth edge with no heat affected zones. It also allows closer nesting of pieces, which saves production time and raw material.

VM&W welds Mild Steel, Stainless Steel, and Aluminum. We also offer robotic welding for your production needs.

The Lincoln Electric Dual Arm System 55 Robotic Cell includes two Fanuc 100 iBe robotic arms equipped with Binzel LEA 500 amp air cooled welding torches.

The cell consists of two work zones. Each work zone has a head/tail stock positioner with a work envelope length of 84” and a turning diameter of 54”. The two arms are programmed with one Fanuc R-J3iC robot controller.

The cell is also equipped with two Powerwave 455M welding units with 450 amp output at 100% duty cycle.

Our Press department uses state-of-the-art CNC equipment including three Trumpf V-Series Trumabends and two NEW Trumpf TruBends. VM&W’s skilled team is ready to tackle your metal bending projects. Whether your project is for automotive, aerospace, or any other industry; we guarantee top notch quality and a quick turnaround.

Our Press department uses state-of-the-art CNC equipment including three Trumpf V-Series Trumabends and two NEW Trumpf TruBends. VM&W’s skilled team is ready to tackle your metal bending projects. Whether your project is for automotive, aerospace, or any other industry; we guarantee top notch quality and a quick turnaround.

Trumpf TrumaBend V-230 |

Trumpf TrumaBend V-130 |

|

|

Trumpf TrumaBend V-85 |

NEW Trumpf TruBend 5320 |

|

|

NEW Trumpf TruBend 8400 |

|

Our CNC Lasers allow for rapid prototyping, greater accuracy, and a faster turnaround than traditional tool driven CNC machines. In the Fall of 2018, we installed our newest Fiber TruLaser that can run up to speeds of 280m/min. See details below.

Our CNC Lasers allow for rapid prototyping, greater accuracy, and a faster turnaround than traditional tool driven CNC machines. In the Fall of 2018, we installed our newest Fiber TruLaser that can run up to speeds of 280m/min. See details below.

NEW! Trumpf TruLaser 5040 Fiber |

Trumpf Trumatic L6050 Laser |

|

|

Trumpf Trumatic L6030 CNC Laser |

Trumpf TruLaser 5040 with Lift Master |

|

|

Monitor, test, inspect, verify, and document parts to ensure compliance with prints and job travelers to meet ISO 9001:2015 and industry standards.

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

CMM experience is preferred.

Must pass drug screening.

High School Diploma or equivalent (GED).

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer.

The Shipping & Receiving Clerk will perform a variety of basic manual tasks involved in receiving, storing, distributing, picking and shipping materials, parts, and equipment. A successful candidate must be also be able to lift boxes, operate a fork lift, and have computer knowledge.

Responsibilities

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

Job Summary

General Laborers perform a variety of basic manual tasks in the production and manufacturing of metal products. Some examples are as follows: Final Assembly and Paint Room.

Responsibilities

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer.

Job Summary

Industrial Painter must have knowledge of spray equipment and paint ovens. Must have knowledge of mixing, blending, thinning and tinting paint, removing old paint, repairing and cleaning surfaces and applying coatings to surfaces.

Responsibilities

Experience

Two years’ experience in Industrial Painting.

Experience with Microsoft Excel and Word.

First Shift: 7:00am-3:30pm; Monday through Friday; Full time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

Driver’s license required.

Employees subject to random drug and alcohol testing.

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer.

Job Summary

Vertical and Horizontal CNC Machining operators must produce quality products that exceed customer expectations on Haas machines. Previous experience and familiarity with tooling and fixturing, Mastercam, PRO-E, and Solidworks would be a plus.

Responsibilities

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

Experience

One year of experience CAM programming.

Three years of experience with CNC.

High School Diploma or equivalent (GED).

Must pass drug screening.

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer

Job Summary

Welders / Fabricators will operate metal fabrication equipment in compliance with company operating procedures using MIG, TIG, and ARC welding processes. They will also be required to become military weld certified in the MIG and TIG processes and able to make some fixturing to meet print specifications.

Responsibilities

First Shift: 7:00am-3:30pm; Monday through Friday; Full time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full time; 5% Premium

Experience

Driver’s license required.

Must pass drug screening.

*On-site weld test and math test will be required.*

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer.

Job Summary

The CDL Truck Driver must be highly motivated, detail oriented, and a dependable team player. The job includes shipping and receiving tasks that allows the driver to be home daily.

Responsibilities

• Performing packing and unpacking of shipment deliveries.

• Preparing shipping documents.

• Maintaining records of incoming and outgoing shipments.

• Managing proof of delivery paperwork from customers.

• Assisting workers in loading and unloading trucks.

• Securing trucking freight by hand.

• Checking mechanical aspects of the vehicle.

• Driving different types of trucks.

Experience/License

• Class A CDL license

• Three years of truck driving experience

First Shift: 7:00am-3:30pm; Monday through Friday; Full time

Driver’s license required.

Employees subject to random drug and alcohol testing.

Excellent Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W is an equal opportunity employer.

The Saw Operator will be responsible for cutting various materials and verifying that the material meets the blueprint specifications, which includes, but is not limited to dimensions, heat/lot number, material grade/type, etc. The operator is expected to maintain the material stock and notify supervisor if the material is running low..

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full-time; 5% Premium

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

The Shipping Supervisor will perform a variety of tasks involved in receiving and shipping products to meet customer demands. Must have previous shipping/receiving experience. Must have experience with Microsoft Office.

Responsibilities

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time; Overtime Available

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

Responsibilities

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full time; 5% Premium

One year of experience is preferred.

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

Brake Press Operator will bend, form, stretch, notch, punch, and/or straighten metal to meet job requirements and quality on part.

First Shift: 7:00am-3:30pm; Monday through Friday; Full time

One year of experience is preferred.

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

The Accounting, Human Resources Assistant will provide assistance in the Finance Department at Verhoff Machine & Welding. Various duties include accounts payable, purchase orders, accounts receivable invoicing, costing reports, and supporting payroll. The applicant will also provide assistance with Human Resource duties including new hires, benefits, time clock, and attendance records.

Job Type: Part Time (24-30 hours a week)

Account Manager will maintain customer accounts, improve relationship, and build the customer base in a combination of an office and shop environment.

Responsibilities

Education and Experience

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time

Driver’s license required.

Employees subject to random drug and alcohol testing

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

The Robot Welder Programmer will set-up and operate robotic welder. The candidate will be responsible for programming and adjusting minor program changes, adjustments to welder, quality inspection, and reworking parts, if necessary. Will also be required to assemble parts into fixtures or jigs, bolt, clamp into position for welding. Mig weld.

Responsibilities

First Shift: 7:00am-3:30pm; Monday through Friday; Full-time

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

CNC Laser Operator will set-up and operate multi–axis CNC Laser performing hole drilling, trimming, slotting, and general sheet metal cutting operations that meet drawing specs.

First Shift: 7:00am-3:30pm; Monday through Friday; Full time

Second Shift: 3:25pm-1:25am; Monday through Thursday; Full time; 5% Premium

One year of experience is preferred.

Driver’s license required.

Must pass drug screening.

High School Diploma or equivalent (GED).

Benefits

Medical, Dental, Vision, STD and Life Insurance, and 401K

VM&W specializes in painting parts for a wide range of industries. We require certification for these different types of paint, from prep to the finished product and are EPA compliant. Our down draft primer booth, down draft paint booth, and primer and paint ovens are all located at our facility, which simplifies the painting process for our customers.

VM&W specializes in painting parts for a wide range of industries. We require certification for these different types of paint, from prep to the finished product and are EPA compliant. Our down draft primer booth, down draft paint booth, and primer and paint ovens are all located at our facility, which simplifies the painting process for our customers.

Industries

|

Part Prep Available

|

Painting Available

|

Our Machining department is offered as a support department to the rest of VM&W. We can put the finishing touches on your project with the ability to turn, mill, drill, chamfer, bevel, and cut keyways. We also have MasterCam off-line programming that assists in reducing down time, which in return, allows our customers to save.

Our Machining department is offered as a support department to the rest of VM&W. We can put the finishing touches on your project with the ability to turn, mill, drill, chamfer, bevel, and cut keyways. We also have MasterCam off-line programming that assists in reducing down time, which in return, allows our customers to save.

Horizontal Machines |

Verticle Machines |

Other Machines |

|

|

|

|

SAWING & SHEARING

SAWING & SHEARING

VM&W has a variety of equipment to handle your sawing, shearing, and iron working needs.

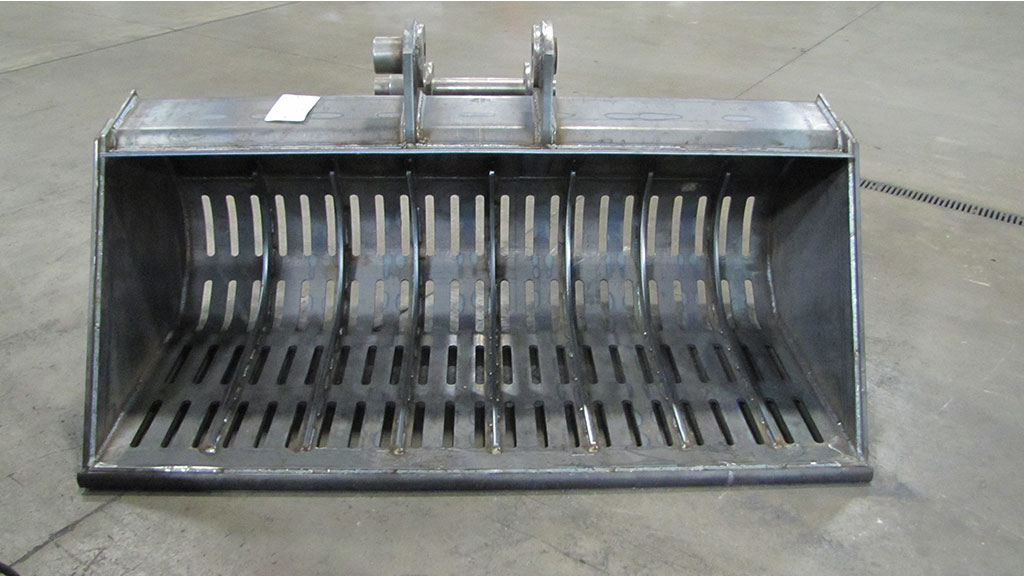

Browse our gallery below to view some of the work we have done for our commercial clients. At Verhoff Machine & Welding we are committed to exceptional quality, precision workmanship, and meeting our customers’ every need.